THE CHALLENGE

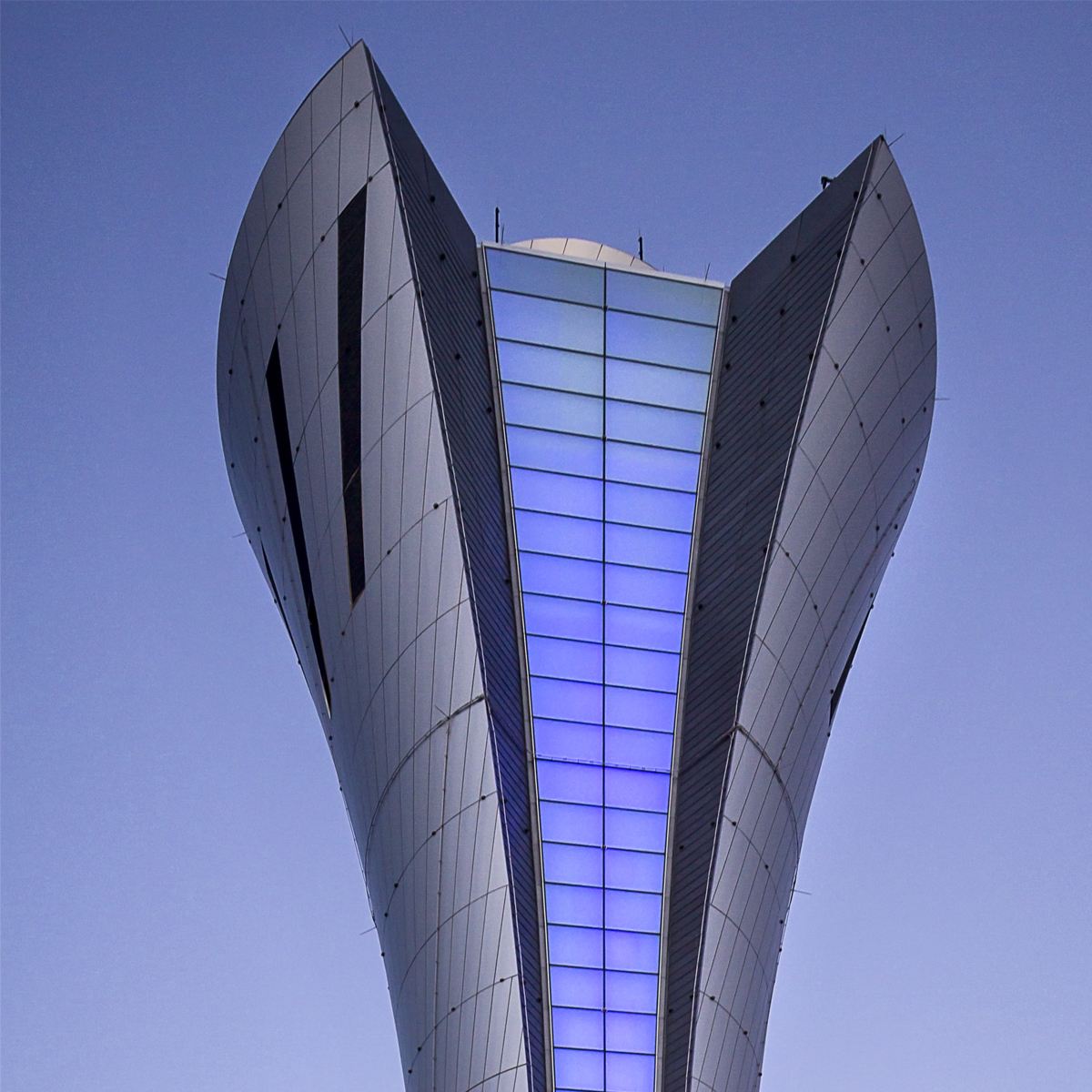

The San Francisco International Airport control tower is arguably the most complex aluminum panel project ever completed in North America.

The immense difficulty of the project stems from the fact that not only does the complex geometry of the panels involve variable radii as the façade rises, but the design also incorporates a helical pattern of joints running vertically.

But this only beings to describe the difficulties posed by the project. The façade had to be installed over a combination of precast concrete and structure steel that was often as much as 2" out of alignment, and yet had to be installed with 5/8" joints to extremely tight tolerances.

So, how was it done?

THE PROCESS

First, a series of structural steel tubes were installed over the surface of the concrete structure, running through the structural steel. These were necessary to support all the elements of the subframing.

Next, a layer of Centria building wrap panels was installed over the steel tubes to provide both an air barrier and insulation.

Then, the most critical element of the structure was installed: a series of steel bands running over the panels installed so as to give a perfect radius at each level of the façade. This steel element was designed and installed by Pacific Erectors.

Only then could the panels, made of 4mm aluminum composite, fabricated by Keith Panel Systems of Vancouver, be installed.

All four structural elements—steel tubes, foam panels, bands, and composite panels—had to come together to make the façade work.

This was achieved thanks to the extensive experience of our crew, not only in installing metal panels, but also erecting structural steel, joints and decking. Meanwhile, our field supervisors had to tackle a variety of complications while ensuring the final delivery of the project.

Their expertise and hard work were vital in making this project a success.

We are waiting for our next challenge.